Robotics is an element that is increasingly pervasive in manufacturing industries. This is the finding from the “World Robotics report 2022” released by IFR- International Federation of Robotics, which paints a rosy future for robotics with a particular emphasis on the Italian market.

According to the report, sales have increased 31% at the global level and 65% at the Italian level, higher even than China’s (+51%) and more than ten times the growth registered in Germany. The growth noted is in regards to not only the traditional automotive, mechanical, and electronic markets, but is transversal to every application sector. In addition, the growth of collaborative robots has been recorded at +7,5%, which remains a smaller number in the world of installed robots but they are reaping a lot of success in non-conventional sectors.

This growth is being driven, among various factors, by reshoring (the relocation of manufacturing practices onto Italian soil) and by the ability of Italian companies and system integrators to create customized machinery that is also flexible at the same time.

ZETAPUNTO, THE IDEAL PARTNER FOR SMES

Zetapunto is one of these. Created in 2015, Zetapunto offers robotic and automation solutions for the cosmetic sector, in particular for packaging and gluing operations. As a systems integrator, the company doesn’t have a catalogue of solutions but provides avant-garde technologies that are then combined to develop the final machine. Custom solutions are made to measure based on the customer and their needs.

Zetapunto’s target is SMEs. The accessibility of these solutions makes them extremely appealing to small and medium-sized companies that often don’t have a great deal of capital to invest in new technologies. “Full compliance to the requisites of Industry 4.0 offers customers a series of economic, technological, and manufacturing advantages: from remote assistance, which drastically decreases the time and costs of an intervention, to predictive maintenance, extremely useful in reducing stops and planning maintenance interventions, to the availability of manufacturing data giving an effective analysis of a plant’s performance or of a single machine’s performance, allowing for effective decisions to be made about the process,” explains Filippo Zechini, founder and CEO of Zetapunto.

And it doesn’t stop at just small and medium-sized enterprises. “Thanks to our dynamic and flexible structure, we can easily interface with small and medium-sized cosmetic companies, offering accessible but high-performing solutions that are capable of meeting the challenges of manufacturing and flexibility with a return on investment in a very short period of time. We’re speaking especially about SMEs, but larger companies can also reap numerous benefits from our solutions. The proof of this came at the latest edition of Innovation Day which was truly a success for us. On that occasion, after having spoken with various key players in the packaging industry, we had yet another confirmation about the transversality of robotics and its extraordinary application versatility“.

FOCUS ON COSMETICS

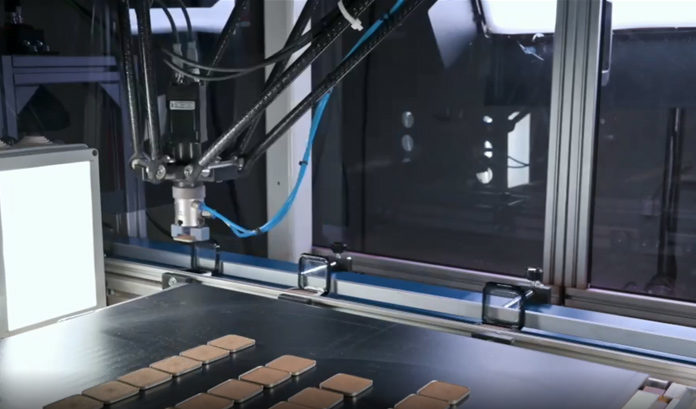

Among the solutions created for the cosmetics world, some that stand out are lines for automatic palette packaging (eyeshadows, blush), automatic loading and unloading for vertical and horizontal cartoning, solutions for orienting products for branding, adding lots, or labeling, robots for gluing products in-line and machines for laser printing on cartons. Industrial robots like SCARA or DELTA for fast applications, vision systems and systems for the transport of products and components, and new collaborative robotics for applications in close contact or synergy with operators.

An industry in which Zetapunto believes strongly and in which it has already set itself apart with successful and avant-garde solutions. “The last project that we developed for the cosmetics sector was for the automation of a stickering machine and the loading of the same product in a vertical cartoning machine for a prestige lipstick, a product that is notoriously known for needing to be manipulated with a high level of attention and precision to guarantee quality”.

Quality that can be monitored at a distance with ease through a video camera. After the sticker application process, the quality is assured via a video camera that verifies the presence and correct position of the sticker on the bottom of the lipstick. The product is then run through a SCARA robot using a conveyor belt and from here it’s picked up with a pneumatic two-fingered gripper and inserted into the individual boxes. A check to make sure the product is present without any contact with the closed box allows for a guarantee of the packaging process quality.

“The project provides for a speed of 40 pieces/min and complete adaptability of the robot to the ebbs of flows of the process, as such to be able to manage anomalies such as missing products (lipstick) or missing boxes on the cartoning line. The system is designed for 4.0 classification and among the characteristics required by the legislation, it’s equipped with remote maintenance and production reporting“.

REVAMPING, NEW LIFE TO OLD SYSTEMS

Another interesting area of robotics application is in revamping, that is, the possibility of giving new life to machinery or “old” plants. An excellent opportunity to contain investment costs and improve efficiency. “Together with the customer, we evaluate the interventions needed for improvement. In this case, our experience mainly revolves around studying the systems for the automatic loading and unloading of machines that are not currently automated or the automatic interfacing between different machines – for example, the unloading of a labeler and the immediate loading into a boxing or cartoning machine”, concludes Filippo Zechini.

In order to satisfy the various requests, Zetapunto pairs its internal development and manufacturing with a large network of manufacturing partners that make labelers, boxing machines, and weighing or branding systems, which provide for coverage of all aspects of packaging and make Zetapunto the ideal partner for automation in the cosmetics sectors.