It’ll be their first time at Cosmopack and it goes without saying that it’s been much awaited occasion and expectations are very high. We’re talking about Zetapunto, the Milan-based company that offers robots and “accessible” automated solutions for companies of all sizes, SMEs included. In Bologna, they will present the numerous advantages of robotized systems through successful, concrete case examples. The solutions offered by Zetapunto are tailor-made, literally “made to fit” the needs of customers like a custom suit. Whether it’s for automating entire processes from scratch or particular stages of the production process, or for “renovating” existing machine set-ups with integrated and avantgarde solutions, Zetapunto’s options are flexible, functional, personalized, and customizable.

There’s no doubting the usefulness and the versatility of these solutions which enable any type of company- small, medium, or large- to improve process efficiency, automating repetitive operations and allocating employees to more relevant duties and tasks for which they’re qualified. An example of perfect man-machine integration. While waiting to meet them at Cosmopack, we posed some questions to Filippo Zechini, CEO & Founder of Zetapunto.

This will be your first Cosmopack. What do you expect from this trade fair?

We’re expecting a lot, for two reasons basically: first of all, it’ll be our first Cosmopack and furthermore, it’ll be important because it represents a return to trade fairs after two years of the pandemic. We’ve been looking to do this for two years and for reasons we’re all aware of, it was cancelled multiple times. Finally we’re ready and enthusiastic to introduce ourselves to such a diverse crowd like that of Cosmopack’s.

Participating is important to us because the cosmetic sector, especially in recent years, has been an optimal field of experimentation for us and we can say that we’re satisfied with how much we’ve grown despite the obvious difficulties of this period in time.

We’re expecting constructive meetings with new customers to be able to show them how to robotize, automating the most monotonous applications with less added value, often indispensable and at a cost that is rarely realized. For us, the fair will be an opportunity to dialogue, both directly and indirectly, with other players of the Italian cosmetics chain, to gain awareness of where the sector’s headed and what not only tomorrow’s challenges could be but also and most importantly, the challenges of the coming tomorrows.

What will you present?

I’d emphasize that Zetapunto is a system integrator and hence doesn’t have a standard product catalogue. Instead, we supply solutions that have been imagined, developed, and made to measure for the needs of each single customer. Cosmopack, for us, will be an opportunity where we will be able to demonstrate our philosophy and our modus operandi, together with various testimonies of projects related to the cosmetic sector. We’ll take it upon ourselves to stimulate discussion with customers, putting the ball in their court to take an interest in automation and to evaluate the optimization of their production processes.

Optimization is a term that I really like. Our solutions benefit from the significant fiscal incentives being offered this year for companies that want to bring in innovation, thanks to the Transition Plan 4.0. In particular, the tax credit for investment in capital goods allows you to recover 40% for investments in technologically advanced assets, such as automatic machines, robots and collaborative robots: this is the reason why it’s fundamental to approach the idea of automation today in order to optimize productivity, taking full advantage of this important opportunity which will change next year. Automate today: this is the message that we want to get across at the trade show.

Will you be participating in other trade fairs in the first semester?

Yes, we have some I mind. In the first semester of 2022, following Cosmopack, as part of Ipack-Ima, we’ll be at Print4All, the historical trade fair for the printing industry where we’ll participate together with our technological partner Zechini Gra.For, as always, with the goal of introducing automation and robotic solutions to small and medium enterprises. In addition, at the end of May, we’ll be participating in Packaging Premiere where we’ll offer robotized solutions for beauty and luxury packaging. It’s very likely we’ll also be at Luxe Pack Monaco in October, the luxury packaging trade show: a sector in which Zetapunto has taken its first steps with packaging robots and in which we still believe today, continuing to plan pick & place, palletizing, and gluing solutions. We’ll wait to see the results of Cosmopack to make other plans.

Let’s just briefly go over the main application fields of your technologies in the cosmetic sector and the advantages that can come about from their use.

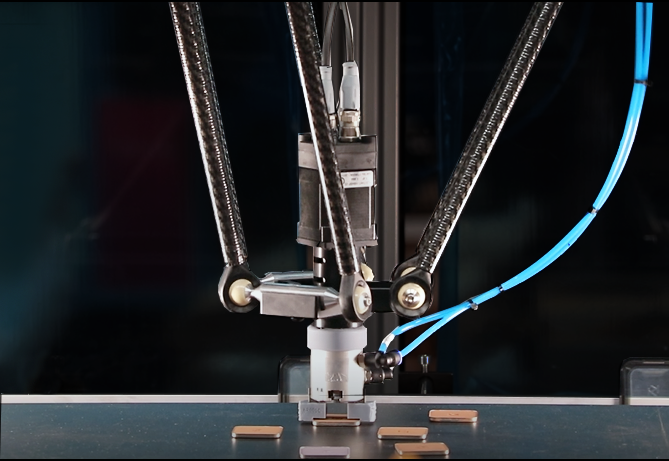

Zetapunto is able to automate many industrial processes, in particular in cosmetics, where we’re now able to cover a wide range of applications. Thanks to the choice of collaborative robots, for example, we can automate gluing operations in an efficient way that would be isolating, repetitive, and less safe if workers were doing them. Over the years, we’ve obtained notable experience with different types of gluing among which include cold glue, vinyl adhesive, hot melt etc. We collaborate with different technological partners with regards to the dosing of different products such as resins or silicones, offering customers turnkey solutions.

Other applications that are largely automated involve the packaging of makeup sets: we’ve developed robots that automatically fill palettes, with one or more colors, with gripping systems guided by camera and various solutions for quality control, from introducing and centering the glue to the correct positioning of the tray in the palette. Also in this case we’ve collaborated with leading companies in the sector to create fully automatic lines, from the opening of the cosmetic bag to the creation and branding of the case.

One of our current focuses are solutions to interface machines that are different, in order to create more automated lines and reduce the need for personnel dedicated to repetitive handling and machine loading tasks, with particular attention to increasing production levels.

What can be done when companies already have machines that don’t need to be completely replaced but only “updated”?

For this type of request, revamping is of particular interest, that is, fixing up machines that already exist that can be made competitive once again from the manufacturing point of view thanks to the specific introduction of automation solutions.

An example that’s getting great feedback is the use of a SCARA robot to manage the movement of products between labelling machines and vertical and horizontal cartoning machines. The use of the robot for this application allows different machines to be put into a line and to reach optimal levels of productivity and reliability during the various steps of production.

The high cost of energy is hitting many companies hard. What kind of energy consumption does your technology have? Does using it in some way help companies?

Energy consumption depends highly on application, in particular if there are thermal processes in play for example, the dosing of hot melt adhesives. In general, you could say that our automation solutions start from a power input of less than 1kW per “stand-alone” robot, up to a range of 4-5 kW with more complex machines and systems. In general, their energy consumption is directly proportional to their use and hence the allocation of their cost is directly attributed to the product that is being handled. The savings for the company occur through waste reduction, both of machined products and supplies, for example glue or adhesives, and an increase in productivity.

The introduction of automation solutions in some cases has also allowed for the reorganization of personnel and the streamlining of production from two shifts to one, with the same number of people: this has an important impact on the cost of staff and on the total energy consumption of auxiliary services like lighting.