The history of Zetapunto – a Milan-based business that has been coming up with robotic solutions for Italian and international SMEs since 2015 – shows how the present is characterized by a steady increase in integration between the work of man and the work of machines.

But, in the popular imagination at least, it hasn’t always been seen that way. Many a movie director, for example, has painted the relationship between machines and humans in a catastrophic light marked by conflict, far removed from today’s reality where robotics and industrial automation serve as valuable tools to relieve operators from carrying out repetitive, tiring and mundane tasks, and to boost industry’s productivity.

ZETAPUNTO’S ROBOTICS

The possible applications of robotics are many and varied as Zetapunto’s custom-made solutions can address a whole host of different production issues and cater to the automation needs of different manufacturing sectors, like cosmetics, packaging, engineering…Above all, though, these are solutions designed for SMEs that don’t always take the place of existing machines and lines, instead often integrating with them and supplementing them in an ever-evolving process.

In this interview, Filippo Zechini, CEO & founder of Zetapunto, tells us about the present and future of robotics, as well as the numerous fields of application of these machines (peppered with examples of past projects).

Zetapunto’s offering can be narrowed down into 4 main lines: custom solutions, integrations, machine tending and revamping. Can you tell us a little about each of these activities?

Zetapunto’s core activity is as a system integrator. In other words, we’re a company that integrates different industrial machines, allowing them to communicate with each other. We don’t sell off-the-shelf machines, what we do is offer is a series of systems, like robots, vision systems, tending solutions, and grippers, which we can then combine, catering to different needs with custom turnkey solutions. This quick overview should give you a better idea of our strength and ability to operate in what, at first glance, might seem like very different sectors.

Above all, we offer custom solutions, namely machines designed for a specific activity that we make with input from our Customers, who are the people most familiar with the process to be automated. These solutions often cannot be replicated since they are “tailor made”.

When it comes to larger plants, on the other hand, it’s more a question of “integration” as our robots are made to work alongside third-party machines to develop a complete, complex line, essentially working either as the prime contractor, or as a subcontractor, depending on the project. If the Customer wants to tackle an existing machine setup, we can produce tending solutions, especially to take over repetitive manual operations, which are inefficient and soul-destroying; or revamping solutions, whereby we salvage equipment that the Customer already has and repurpose it for new projects.

On the subject of integration, you have an interesting example for the cosmetic industry, in the filling of palettes. Can you tell us what you did and in what cases integrating a new machine into an existing system might be the best solution?

In the cosmetic industry, assembly is one of the many operations that Zetapunto can automate successfully and to the great satisfaction of the Customer. More specifically, filling palettes demands a high level of accuracy and repeatability and, for the most part, it’s still performed by hand.

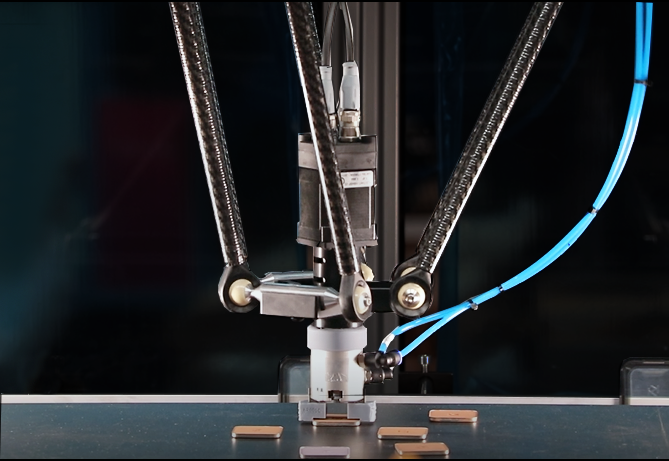

We recently developed a robot capable of accurately and efficiently performing gluing – in dots or in a number of lines – and filling palettes with pans, like eyeshadow, blusher, etc. These activities also include quality controls, like checking that the dot of glue has been applied and is centred, or that the pan is facing the right way relative to a logo or writing, or that the pan has actually been placed inside the palette.

These solutions have been integrated with labelling machines and box forming machines for the design of a fully automated complete assembly line.

A long and complex job that also called for collaboration with third-party suppliers and tech partners…

Yes, true story. Implementing this integration involved a lot of research into third-party suppliers and tech partners who were needed in order to understand and use technologies foreign to Zetapunto. In addition, in parallel, purpose-built systems were developed to allow for integration between the various machines. For example, we’ve produced a manipulator robot to pick the palettes up off the line as they exit the labelling machine, to then place them inside the box forming machine. The robot produced is capable of interfacing with both machines downline and upline and sync with them in order to optimize the performance of the resulting line.

What industries other than cosmetics do you work in?

The range of industries Zetapunto can work in is potentially huge, given that automation has a virtually unlimited reach. For instance, we’ve designed and produced solutions for the engineering sector, automating the gluing of parts for the automotive industry, using a robot to punch blanks, in addition to designing magnetizing solutions incorporating an anthropomorphic robot.

Another industry we specialize in is packaging, more specifically with robotic pick&place, packaging and box gluing solutions. Generally speaking, we operate in all manner of industries, automating activities of various kinds. Our list of successes also includes examples in the pet world, with robotic solutions for putting together pet name tag packs; and in the field of sport, with robots used to glue ski goggles.

What are the fields of application of Zetapunto engineering?

The areas we operate in are parts and components handling and the automation of fluid dispensing processes in the cosmetic industry, such as dispensing he right amount of glue into palettes.

What does your parts and components handling offering look like for automation?

You have basic robots for transferring products between lines, then you have tending robots for loading/unloading machines that – in the cosmetic production process – are used in filling bottles on manual or semiautomatic lines, or in more out-there applications for loading vertical and horizontal box forming machines, where syncing between the robot and machine is essential.

Handling entails, first and foremost, deciding on the type of robotic arm and, more generally speaking, what automation is required to perform the movement. Then, we need to do a full-on analysis of the gripping system, also known as the gripper, which varies hugely depending on the type of product to be handled and the required speed. Simple handling can be performed with one or more suckers or, for a stronger hold and to achieve higher speeds, a pneumatic clamp may be needed instead, or even an electric clamp, for handling different products within the same cycle, or for faster format change.

There are so many variables involved. And drawing on our experience and our know-how, we can come up with the best solutions to make the Customer’s manufacturing operations more efficient and effective, meeting their expectations and demands.

Let’s talk about the other field you’re specializing in, the automation of fluid dispensing processes. What is it you’re offering here?

The term “dispensing” covers a whole range of very different processes, covering all manner of applications: in the lighting industry, silicone needs to be dispensed onto light bulbs for an airtight seal, while in the sensor and motor field, 2K resin is dispensed to isolate soldered electric contacts. These operations are often still carried out by hand, or by 3-axis Cartesian robots. Nonetheless, we’re inclined to offer our Customers collaborative robots, which allow for greater operational flexibility while leaving options open for possible repurposing in the future, should the application in question change.

Am I right in saying that Zetapunto can work alongside the Customer in developing a “Digital Factory”?

Yes, yes you are. To qualify as 4.0, the plant has to meet a certain number of requirements, and here again Zetapunto has gained experience over the years required to assist Customers in their preliminary ROI analysis.

The digital factory is a new factory concept that was theorized in Germany in 2011 and introduced operationally in Italy in 2016 by the Ministry for Economic Development with the Business Plan 4.0. Generally speaking, it’s an industrial plan that aims to stimulate functional investments in new technologies, with a view to producing next-level technology.

In more operational terms, the plan is geared towards promoting greater business digitalization, especially in two areas: 1) more control over manufacturing and a greater focus on waste. Processes are more closely monitored and more data are gathered on manufacturing, the aim of which is to analyse them and successfully prevent critical issues or identify wastage that leads to lost productivity;2) preventive maintenance: having more production information available means machine manufacturers also have access to more data on how machines are being used, thus allowing them to set out scheduled maintenance plans. Unlike non-routine maintenance – which is typically required to address a sudden fault – scheduled maintenance has a lot less impact on a plant’s productivity, because it can be planned beforehand to coincide with times when the plant is usually offline, and is less of an expense for the Customer.

The plan also promotes greater use of technology and automation, in order to speed up processes and make them more consistent, as well as to relieve human operators from heavy, repetitive and draining tasks, freeing them up to perform higher value-added operations. In past years, the incentive came in the shape of enhanced depreciation, morphing in more recent years – and, most likely, into the future too – into a tax credit amounting to as much as 50% of the value of the plant.

Data from the automation industry reveal strong growth in the industry. Can you confirm this trend? Working in various sectors, which have been the worst hit by the pandemic and which have instead weathered the storm best? In your experience, which industries are seeing the biggest bounce back?

Yes, we’re seeing a positive trend and there’s optimism for a recovery, even though we have Customers who are waiting until the autumn is truly here before resuming investments in earnest.

Because many operations can be automated in industries, and manual work is often soul-destroying, repetitive and draining, and is not particularly efficient, we – as system integrators – are receiving requests to automate these kinds of processes from all manner of industries.

When it comes to the Italian market, which is our target market, we’re experiencing this growth in two sectors above all: the engineering and cosmetic-pharmaceutical industries.

Let’s start with the engineering industry…

The engineering industry we serve is not just related to automotive – which certainly has the lion’s share of volumes – we’re mainly focused on that part of the industry associated with small and medium enterprises, which excel in the production of quality parts, even handling small batches.

In this sector, manual operators are essential for their flexibility and technical ability, but they’re becoming an increasingly scarce resource. Hence we collaborate with various companies that are looking to robotics to relieve qualified operators from menial chores, such as simple machine loading/unloading, so that they can be employed for higher value-added tasks, such as setting up a new production run or supervision.

What about cosmetics, what’s happening there?

The pandemic has had a lopsided effect on the cosmetic industry, depending on the type of product.The need to use masks has had repercussions on makeup, above all, especially on the demand for products like foundation and lipstick while, at the same time, it’s boosted demand for eye products, including eyeshadow and mascara, and especially cleansing and cosmeceutical products.

We’re currently experiencing a boom in collaborative robots, which are based on collaboration between human operators and robots. This has led us to design and produce various solutions in different areas that strike a balance between the need to automate those less efficient processes and the role that the human hand plays, which is still very much seen as essential.

Our task is to help the Customer choose the right automation for their specific production process. As a concept, a collaborative robot can be very appealing, but its effectiveness in the production setting must be validated with an analysis that also takes into account other parameters, such as production rate, accuracy and reprogrammability. For this reason, the early study and analysis stages are key to offering the Customer the automation they truly need, and it’s also the reason why our solutions include different industrial robot architectures, ranging from collaborative for its flexibility, to SCARA and Delta robots for high-speed applications.

How do you see the future of industrial automation?

We, of course, believe strongly in its growth and in its development within the industrial fabric. From the handling of small parts to box or product assembly or tending, automation is playing an increasingly starring role in manufacturing and control processes because it provides the worker with the opportunity to perform non-draining duties, while the company benefits from a significant increase in productivity. Not just in engineering or cosmetics, but in many other industries besides.

If the forecast trend comes to fruition, this post-lockdown period may well be a great growth opportunity for businesses who manage to adopt these technologies, partly with our help.