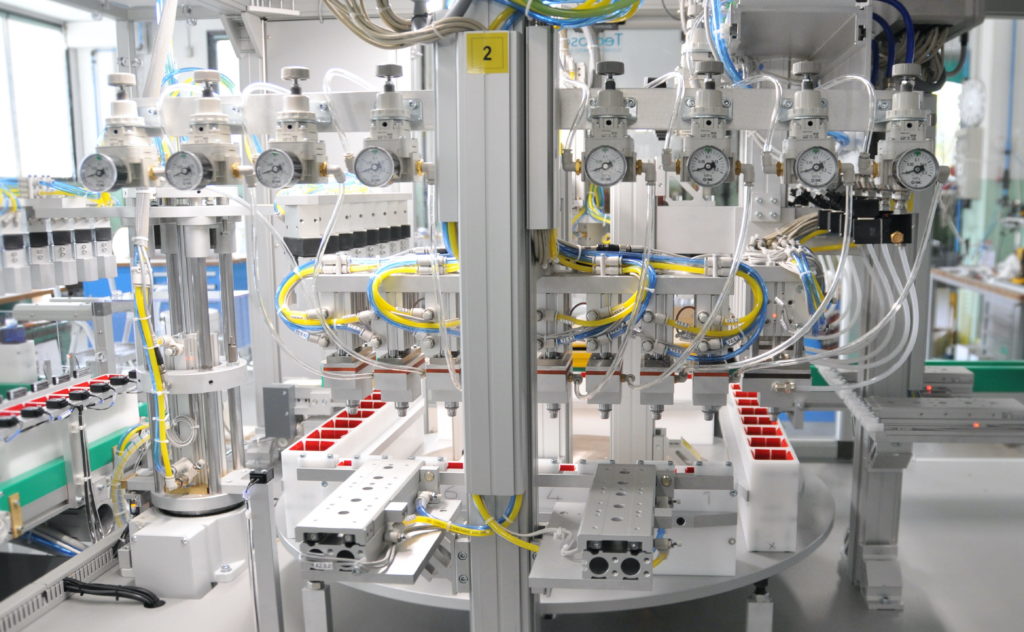

The concept of “tailor made” is epitomized at Tecnosas. This would account for the fact that so many businesses turn to Tecnosas to handle their special, unique, “outside-the-box” projects. Based in Grantola, in the province of Varese outside Milan, the company — which has been making special machinery for the decoration and assembly of cosmetic packaging since 1995 — has extended its product range in recent years with the addition of palletizers, case erectors, and filling, screen-printing and pad-printing machines.

Different machines that nonetheless share a common denominator: they are all “tailor made” for the customer. There’s no standard or mass production here, just 100% custom-made projects that combine the expertise of Tecnosas with that of the customer, in a process of mutually beneficial exchange and continuous growth.

As Eleonora Santagostini, Sales Director explains, “Our machines are the result of our thirty years’ experience in the industry, and that of our customers. Customers come to us for custom solutions: machines that can handle complex or very special operations, which are hard to achieve with mass production, because they know our philosophy is creating a product that’s so made to measure that the tech and production solutions adopted for a customer are not replicated on any other machine or any other project. How would I describe our production? Absolutely bespoke: not only are our machines unique, they fit like a Savile Row suit.”

2021 SEEING STRONG UPTREND

A philosophy founded on years of experience and taking customer feedback on board, as well as on attention to detail and continuous innovation. While still the size of a family business, Tecnosas has managed to leverage these elements to earn itself a place of honour in the industrial automation sector and successfully tackle the market’s growing challenges.

“Following the lengthy months of the pandemic and with many manufacturing operations in lockdown, we expected an increase in demand, but we didn’t expect such a high and concentrated demand. It was a positive surprise, but one that meant we also faced a number of management issues, such as how to meet increasingly short delivery deadlines and cope with the rise in component and raw material prices. It’s not easy, especially for a company like ours, to absorb a portion of the costs and meet increasingly tight lead times, but this is all part of being there for the customer: going the extra mile. What are customers asking for most right now? Mainly new machinery or modules that can be integrated into existing systems with a very clear goal: to drastically increase (in some cases, we’re talking about even doubling) the parts per hour rate.”

MARKET DEMANDS

In addition to high productivity and low running costs, one of the increasingly frequent market demands is for machines that provide increasingly detailed information on the processes in progress, with a view to boosting cost-effectiveness across the whole production process.

“The number and type of information requested by customers has grown unbelievably in recent times because they want to have an exact, detailed picture of what’s going on during the various process steps. Customers today want to know not just the amount of reject parts, for example, but why they’ve been rejected and during what stage of the production process: that way, they can identify problems, find possible solutions to solve them and limit waste. Another aspect they ask us to be able to monitor is the time taken by the machines to carry out the various activities (control/assembly/loading). The detailed analysis allows them to highlight any inefficiencies and take action to maximize productivity. Customers can always count on our help with these assessments and in optimizing the machine’s features.”

WORKER SAFETY AND SIMPLICITY

Worker safety and simplicity of use are also hot topics. Customers are asking manufacturers for machines with increasingly meticulous and reliable safety devices, as well as versatile solutions designed to cater to diversified needs. To this end, over the past few months, Tecnosas has actually been working on a special machine with a module-based table: by simply swapping out the modules, the machine can be adapted to handle parts of varying complexity, different materials, different lot sizes and the required work rates. As Eleonora Santagostini finishes up by saying, “A highly customized project that reflects our philosophy to perfection: producing tailor-made technologies for the cosmetic and makeup industry.”