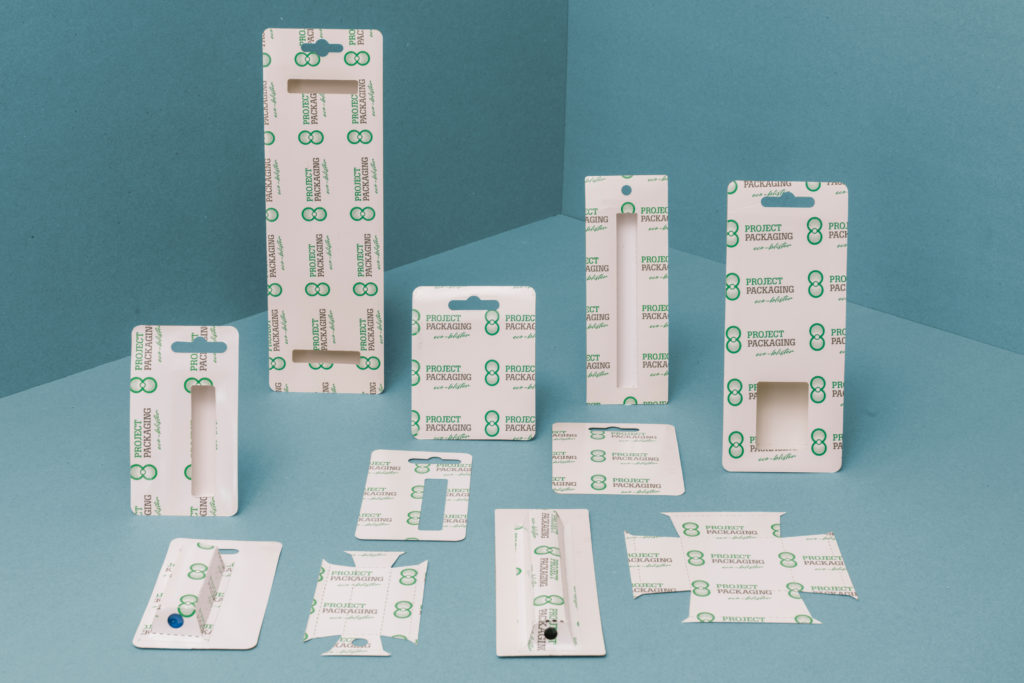

Sustainability is the future. It is this deeply felt conviction that prompted Marco Pedrini, founder of Project Packaging, to invest in a new machine for producing blister packs made entirely from paper, with the aim of reducing the use of plastic to zero, at the same time delivering excellent performance. A game-changing decision that makes the company from Campagnola Cremasca one of just a handful in Italy in a position to offer customers this innovative solution.

CUTTING-EDGE PAPER

“The machine will be up and running very shortly – we’re told by Pedrini who, in 2007, created his business that specializes in blister packaging for retail chains and supermarkets and has also become the go-to choice in thermoforming and contract packaging for cosmetics, as well as for other product sectors – and will produce eco-friendly blister packs, capable of completely taking the place of current cases/blister packs made from thermoplastic material. We’re very proud of this decision since the packaging machine in question is unique, and we’ll be one of the first in Italy to adopt it. That way, we plan on attracting a new target of potential customers, at the same time helping them on their sustainability journey, developing new secondary packaging projects with environmentally friendly blister packs made from paper.”

THE ROAD TO SUSTAINABILITY

A starting point rather than a finish line: 100% green blister packaging is just the first step towards other similar initiatives based on the principles of ecosystem integrity, economic efficiency and social equity. “While extending our product range with the new eco-friendly paper blister pack certainly addresses the needs of our current and potential customers – Pedrini comments – above all, it ties in with a wider Corporate Social Responsibility agenda that concerns products, production and people. We’re an SME with 10 employees. Our aim, of course, is to grow, but to grow with a sustainable mindset, drawing on our passion for the work we do and making responsible, shared decisions“.

ECO-PACKAGING MADE WITH NEW CONSUMERS IN MIND

Project Packaging has always used fully recyclable raw materials (PET, PVC, PS, PP), and handling trays optimize production, limiting wastage and hence ultimately reducing the amount of waste produced. Pedrini stresses that “The issue of sustainability is the future. We have been working with 100% recyclable PET plastic for years, but in the coming months we’ll be integrating our product range and our offering with other plastic-free solutions to cater to the numerous demands not just from our customer companies, but also taking into account the demands of their end consumers, who are increasingly aware and attuned to these issues. Our message is simple: we’re ready to help you with tangible responses and effective solutions.”

ITALIAN MADE AND TAILOR MADE

One of the distinguishing traits of the modus operandi at Project Packaging – whose signature products, alongside blister packs, include thermoformed clamshell packaging and trays – is the technical advice aspect, enabling the company to offer customers a one-stop service. Pedrini finishes up by saying “The Made in Italy brand principle is very much part of our business with its strong emphasis on craftsmanship. However, we have a great understanding of the industry’s market and hence the aim is for us to offer a full service: from the design to production of packaging engineered to meet customer demands and enhance the product, all the way through to packaging and delivery of the resulting goods. We provide customers with the option of a quality, custom product, but at competitive prices.”