This is what Ivan Riboni, CEO of IDM Automation, tells us about these past months and ongoing projects.

“Despite the fact that the decline in make-up production due to the pandemic has severely penalized us in recent months, we have never stopped. We have continued to innovate and invest in new projects. One above all: the move to a new location, also in Vigevano, which perfectly meets the increased needs of the company, giving us greater functionality, larger spaces to work in and a faster, more streamlined workflow. Although the inauguration will have to wait for the moment, it is an important milestone for us“.

Despite the slowdowns due to the epidemic, the company has continued their work, focusing especially on innovation and development. IDM has been on the scene since 2009, making automatic systems for filling mascaras, eyeliners, lip glosses, and nail polishes, as well as dosers, melters, cleaning machines for baked products, and robotic assembly systems.

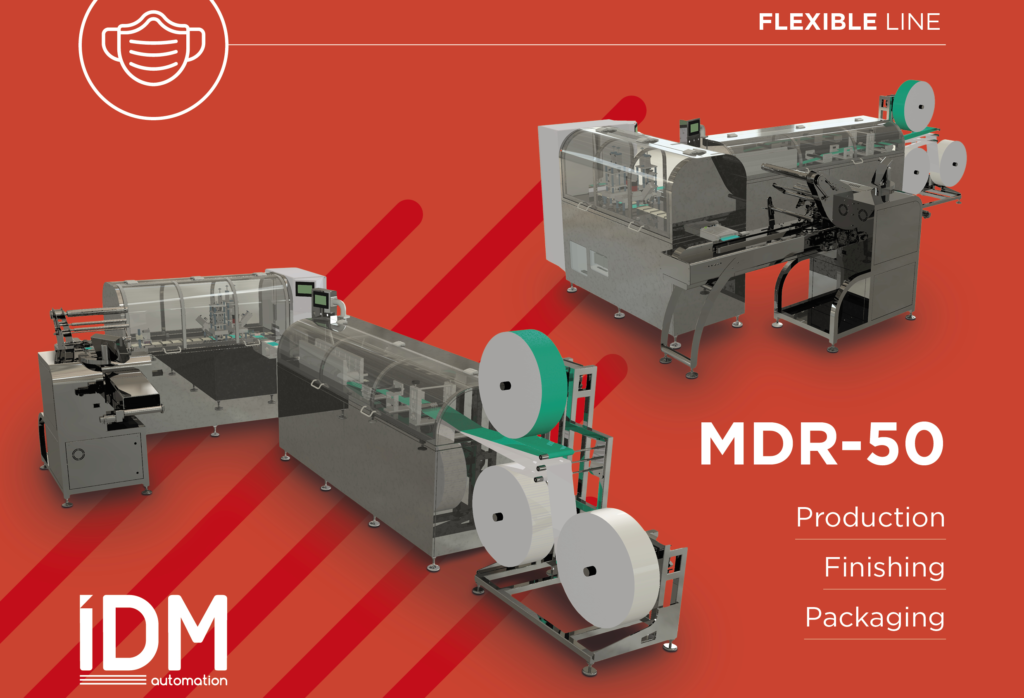

NEW PRODUCTS: A SANITIZING GEL FILLING MACHINE AND A SURGICAL MASK PRODUCTION MACHINE

“During the lockdown months we reflected on the situation and wondered what we could do to respond to the ongoing emergency with something concrete. Our answers were: MSG-1-120 and MDR-50. The first is an ATEX-certified sanitizing gel filling machine, capable of processing flammable materials, such as alcohol contained within gels, and created by modifying the design of an existing filling machine; the second is a surgical mask production machine.

A concrete response to a concrete need.

“Our goal was to offer two functional and efficient machines, 100% Made in Italy, with quick delivery times. And we’re happy to say ‘mission accomplished’, we are able to provide these machines from order to delivery in just two months. And the Made in Italy production? Guaranteed in full because in addition to the machine, we can count on partnerships with Italian textile companies and provide, when asked so by the customer, a finished product that is 100% Made in Italy“

FULL ELECTRIC, GREEN AUTOMATION

IDM Automation also has expansion to other markets in the works. “Even though cosmetics” – the entrepreneur points out – “will always remain our core business”. Hence, new developments are certainly not lacking around here. In addition to two new powder machines, a Back/Side Injection machine, and a compacting machine for powder with dowel technology, the focus is on the development of Full Electric technology and Industry 4.0, already key elements of IDM Automation’s strategy.

“For us, Full Electric technology” – concludes Riboni – “represents the future of automation in a sustainable way. Its use also offers several immediate benefits. From reducing consumption to increased product safety because it eliminates potential elements of contamination, there’s also an improvement in production performance to the point of achieving quieter operation of the machine itself. Our goal is to apply this technology across the board to all the machines we produce from here on out. The future of automation will be green.”