“Tapematic hasn’t stopped in the last few months. Even in the two weeks where everything was completely stopped, through our employees who were working remotely, we were able to guarantee our customers worldwide technical support, spare parts, and supplies. We continued to work to ensure service to those customers who, belonging to the supply chain of basic necessities, continued to work even during the lockdown”.

These are the words of Davide Perego, Executive Director of Tapematic, the Ornago (MB) company that has been designing and developing the highest quality machinery for UV coating and packaging metallization since 1970. Though it is a business focused mainly on the cosmetic world, it also has some interesting operations in the beverage, pharmaceutical, and automotive industries.

COVID19 AND THE 2020 FORECAST

“The pandemic has blocked, or at least substantially slowed down, all activities related to new business, I am referring mainly to visits to and from customers, as we have continued with the development of existing projects and open orders. The decline is undeniable. However, business has held on enough and we expect to close the year with a decline around -20%”, continues the Manager.

“I have to say that in Europe and the USA, governments have launched measures to support companies and this has led several companies to choose to invest in new machinery, despite the critical nature of the global situation at the moment. Many are doing so with the aim of further internalizing production with significant benefits in terms of cost and quality of the final product. And our systems are the perfect answer to this because our philosophy is very simple and immediate: guarantee the customer high quality decorations thanks to production lines made up of our automated machines that are easy to use, modular, and developed and produced entirely in house“.

BEST SELLERS: PST LINE 1 E PST LINE 2

High technology standards allow Tapematic to offer custom solutions that meet each customer’s needs, with a common denominator: a focus on cost reduction and environmental protection. For Tapematic, sustainability is not an abstract concept but something that directly results in the development of machinery that focuses on efficiency and overspray reduction.

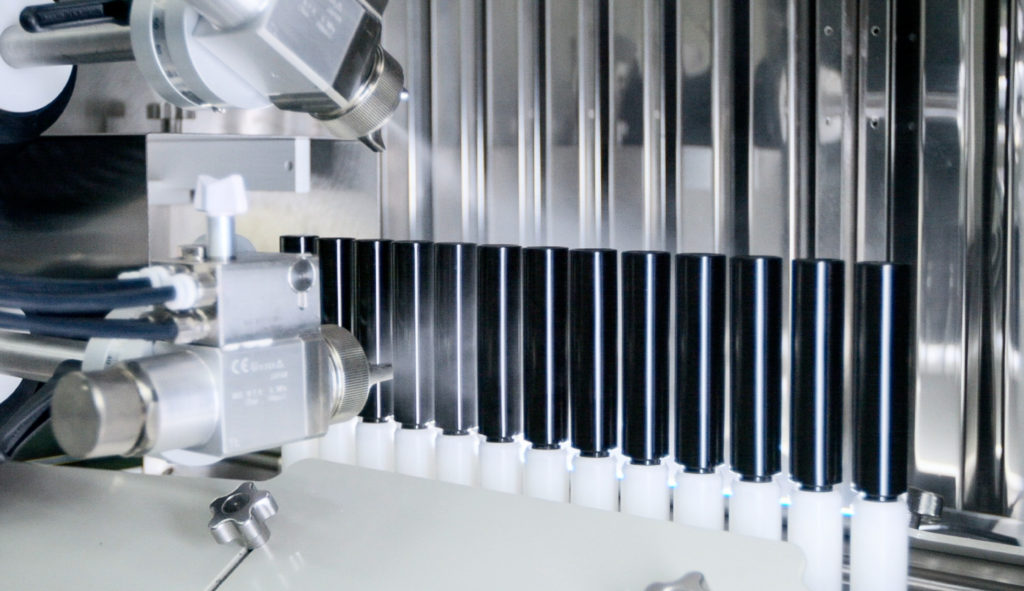

All this means benefits for the environment and for the company itself, which, by reducing paint emissions and waste in the environment, produces a more environmentally friendly product with a lower production cost. Tapematic’s philosophy is well-represented by PST LINE 1 and PST LINE 2. Two machines for UV coating and metallization that are fully automatic, modular and adjustable, able to work on 2000-4000 pieces/h (PST LINE 1) to 7000 pieces/h (PST LINE 2).

THE NEWS IN THE PIPELINE: IDM – IN LINE DECORATION MODULE

The company also has some great new products in the works, which will be officially launched on the market in the second half of the year.

“IDM- Inline Decoration Module will be a revolutionary machine for the industry because it allows you to do hot printing in line with UV coating without having to move the pieces and with the ability to add variable data as well. In terms of product quality, delivery times, and final costs, the advantages will be substantial. We would like to organize an Open House by the end of the year but it will all depend on how the situation develops.”