A qualified partner, able to manage the development of entire automated lines: from the study of single “pieces” right up to the on-site installation of the machinery at the final customer. This is the calling card of CB Automation, a division of F.lli Bettinelli Spa, a leader in industrial automation for the pharmaceutical, medical, and cosmetic sectors.

CB Automation’s mission is to offer customers their know-how gained over years of experience in the business in order to create automated assembly lines that are technologically-advanced and reliable, with multiple benefits including respect for the environment.

PIONEERS IN SUSTAINABILITY

In addition to the human side of things, nature and technology have always been key aspects in CB Automation’s philosophy. As a true pioneer in the sector, the company developed its first “Full Electric” machine more than ten years ago.

Technological innovation, respect for the environment, and quality service find a perfect balance in the company’s vision. Consistent with these principles and among the first companies in Italy, CB Automation obtained ISO 9001:2015 certification in 1998 and today, following the same philosophy, is working on meeting the requirements for ISO 14001 certification.

In 2020, CB Automation made an immense effort to guarantee support to the local community and at the same time, worked very hard on the development of technological infrastructure to guarantee constant service its customers all around the world. The future is in continual flux and CB Automation is ready to face the next challenges: sustainability, technological innovation, and energy saving.

TECHNOLOGICAL INNOVATION AND DIGITAL TRANSFORMATION

Since the beginning, CB Automation has been intensely focused on innovation, as a result, ensuring a high degree of flexibility and service quality. The company has always been geared towards automation and computerization and immediately seized opportunities offered by Industry 4.0.

But innovation, as the General Manager explains, is an ongoing process that constantly brings up new challenges to face. And the next ones for CB Automation are: technological innovation, sustainability, and energy savings.

“The future is made of challenges and the most important for the industrial automation sector is represented by technological innovation, that which is defined Industry 4.0 and that brings with it, the digitalization of processes,” says Franco Chiozzi, Engineer and General Manager. “As far as we’re concerned, in the last years we’ve invested a lot in IT infrastructure and in tele-assistance technology: investments that have proved to be rewarding and that today, allow us to remotely interact with our machines in every part of the world and in every moment.This allows us to offer our customers a series of avant-garde services: technical assistance and problem solving, training for technicians, certification, updates and modifications to the machinery“.

ENERGY SAVING AND SUSTAINABILITY

For CB Automation, looking ahead is a mantra that is revolving more and more around the concept of eco-friendliness.

“Environmental sustainability and the policy of energy saving have always been part of the company’s DNA. The projects and initiatives that have been undertaken these past few years demonstrate this: from the creation of electric machines that currently represent our core business to the installation of solar panels at our headquarters which today, provide 30-40% of our energy requirements, up to the increasing use of first grade energy sources”.

ONE SOURCE SUPPLIER

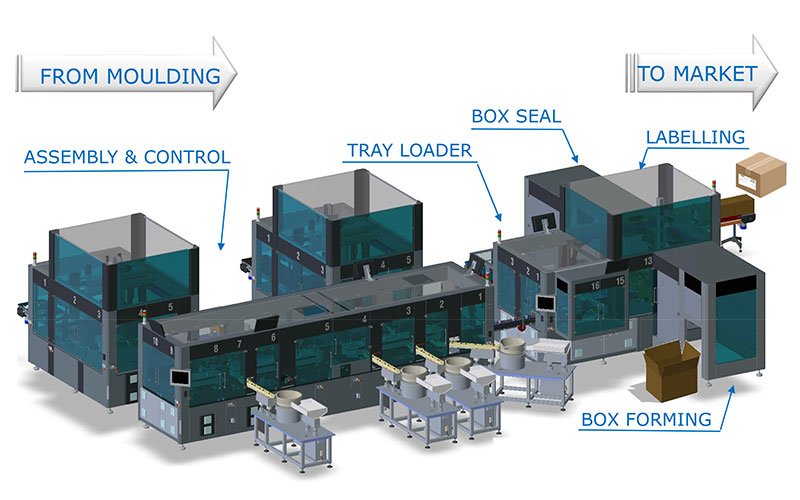

Despite the difficulties linked to the pandemic, in 2020 production never stopped and just at the end of the year, CB Automation presented two complete lines that perfectly encompass its one source supplier philosophy: the LBB1994F and the LZA1867G.

“These are platforms that are an excellent representation of our philosophy of a one source supplier and the multiple benefits that come from the use of automation in the cosmetics industry,” explains Chiozzi.

ENTIRE AUTOMATED LINES

The two lines, which are an answer to market demands, blend key elements of modern-day automation: efficiency, ease of use, and flexibility.

“The LBB1994F, in particular, is a platform interfaced with the mold in which the robot unloads the components from the mold onto a buffer. The components are taken four at a time from the buffer and deposited two at a time on a table, where the first quality control check takes place. The piece is then transferred onto line B and assembled with another two elements which are supplied in two different ways: the first by a depalletizer and the second through a hopper feed system. Once assembled, the sub-assembled product undergoes another two quality control checks and is then unloaded onto a belt that transports them to a palletizing robot. These latter trays will be processed on another line that was also developed by us. This machine, in its complexity, clearly shows our ability to offer a turnkey product that meets customer requirements perfectly. In the LZA1867G, the other line presented at the end of 2020, the robot is integrated into a machine that assembles boxes, closes them and then labels them. At the end of the line, the fully-traceable cartons are ready to be shipped all over the world”.